5 Surprising Truths Hidden in a Bill of Materials

5 Surprising Truths Hidden in a Bill of Materials

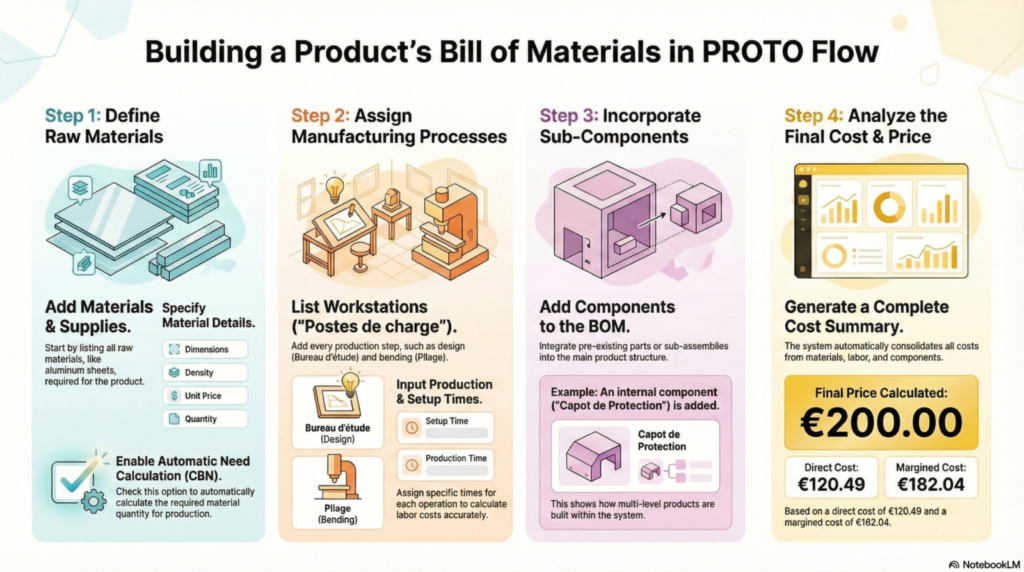

Introduction: The Master Recipe for Everything

Have you ever looked at a common object—a desk lamp, a kitchen tool, a piece of equipment—and wondered what it truly takes to manufacture it? Your first thought might be a simple shopping list of parts. But the reality of modern industrial production is infinitely more complex.

At the heart of this complexity lies a document called the Bill of Materials (BOM), referred to as "Nomenclature" in the provided system. It is the central "master recipe" that manufacturers rely on to turn raw ideas into finished products. This article will explore the surprising depth and power hidden within this fundamental tool, using screenshots from the PROTO Flow Enterprise system as our guide.

A BOM Is More Than Just a Parts List—It's the Entire Story

1. It's a "Recipe on Steroids," Not Just a Parts List

A common misconception is that a BOM is simply an inventory of raw materials. In reality, a modern BOM is a comprehensive blueprint that integrates three critical questions into a single structure:

- What you need (Materials & Supplies - Matières/Fournitures): The physical 'ingredients' like the aluminum sheet (ALUMIRO8).

- What you do (Manufacturing Operations - Postes de charge): The 'instructions' or process steps, like engineering (BUREAU D ETUDE) and bending (PLIAGE).

- What you use (Sub-Components - Composants): Pre-built 'modules' that are incorporated into the final assembly. These are often designated as 'internal components' (COMPOSANT INTERNE), which are themselves products with their own BOMs.

This holistic view creates a single source of truth for an entire product. This prevents costly disconnects where engineering designs a product, procurement buys materials for an older version, and the shop floor is equipped for something else entirely.

The Power of Radical Granularity

2. Every Detail Is Tracked with Incredible Precision

The true power of an enterprise system's BOM lies in its extreme level of detail. This granularity isn't just for record-keeping; it's the foundation of the entire manufacturing plan.

Consider these specific examples from the system:

- Materials: The system doesn't just list "aluminum." It tracks the specific reference ALUMIRO8, its exact dimensions (DIM 1250X2500 ÉP 0.4MM), its material density (2,80), and calculates the precise required weight for the job (0,044 KG).

- Operations: Time isn't measured in broad strokes. Every manufacturing step is broken down into Temps de Production (Production Time) and Temps de Réglage (Setup Time). For the PLIAGE (Bending) operation, the system specifies 0,083 H of production time and 0,25 H of setup time.

This isn't just accounting; it's foresight. It means knowing your precise profit margin on a job before you quote it, and confidently committing to a delivery date you can actually meet.

The Elegance of Hierarchy

3. Complex Products Are Built Like Russian Dolls

How do manufacturers manage the assembly of products with hundreds or thousands of parts? They use a hierarchical, or multi-level, BOM. Think of it like a set of Russian dolls, where smaller dolls (sub-components) are nested inside larger ones (the final product).

The "Arborescence" (tree structure) view in the system perfectly illustrates this concept. It shows that the main product, [Niv. 00] TOL0995A, contains a distinct sub-component, [Niv. 01] 001810 X2. This sub-component has its own complete set of materials and operations. This 'Russian doll' structure is the key to manufacturing at scale. A single, validated sub-component like 001810 X2 can be used across dozens of different end products, drastically reducing design time, inventory complexity, and testing.

The Unbreakable Link Between Operations and Finance

4. Every Screw and Every Second Has a Price Tag

A modern BOM is not just an operational document; it's a financial one. The "Tarif" (Pricing) tab is where all the granular operational details are translated into cold, hard numbers.

The system meticulously rolls up costs from every single element defined in the BOM. The "Synthèse de la nomenclature" (BOM Summary) view provides a clear breakdown of where the costs come from:

- Fournitures (Supplies)

- Composant (Components)

- M.O. (Labor)

- Réglage (Setup)

These individual costs are summed to create the total COUT DE REVIENT (Cost Price), which for this product is 120,49. This forges an unbreakable, auditable link between the activities on the factory floor and the final cost of the product. This traceability is a powerful diagnostic tool. If margins shrink, a manager can instantly see if the cause was a spike in the cost of Fournitures (Supplies) or an increase in M.O. (Labor) time on a specific operation.

A Strategic Tool for Profitability

5. It's a Profitability Engine, Not Just a Cost Tracker

The final and most powerful truth is that the BOM is a strategic tool for managing profitability. This is evident in the "Tarif" tab's distinction between two primary cost columns: Direct (Direct Costs) and Margé (Marked-up Costs).

This feature elevates the BOM from a simple accounting tool to a strategic one. It allows the business to see not only the raw, direct cost of production but also exactly how margins are applied to each cost component—materials, labor, components, and setup. The final PRIX VENTE (Selling Price) of 200,00 and the calculated COEF. MARGE (Margin Coefficient) of 1.511 are the ultimate outputs of this process. Beyond simple tracking, this allows for powerful 'what-if' analysis. A manager can instantly model the impact of a 10% increase in material costs or a 5% improvement in labor efficiency on the final selling price and margin.

Conclusion: The Digital DNA of a Product

As we've seen, a modern Bill of Materials is far more than a simple parts list. It is the comprehensive digital blueprint—the "DNA"—of a product. It seamlessly connects engineering design, manufacturing operations, and financial strategy into a single, cohesive, and incredibly detailed system.

The next time you use a manufactured object, will you think about the incredibly detailed digital story that brought it into existence?